Triple G resist

A tough structure built to withstand the three main types of gravitational acceleration: dropping shocks, centrifugal force and vibrations.

Shock-resistant structure

A hollow case structure protecting the module from external shocks, cushioning of key parts inside the module, cushioning protection from direct shocks by a unique case-and-bezel form, and an all-directional guard structure to mitigate impacts are all combined in a structure built to resist dropping shocks.

Centrifugal gravity resistance test

Watch hands that are required to move in an environment of strong centrifugal gravity are liable to rotate due to their own weight, which may cause breakage. We therefore calculated the weight balance of each hand with precision and arranged It optimally. The result is stable hand movement, even under conditions of strong gravitational pull.

Centrifugal gravity resistance test

We realized the ability to withstand centrifugal forces exceeding the highest level (centrifugal gravity up to 15 G) classified by the ISO 2669 steady-state acceleration environmental test for aircraft equipment. The results confirm that the various functions operate normally under conditions of extreme centrifugal gravity

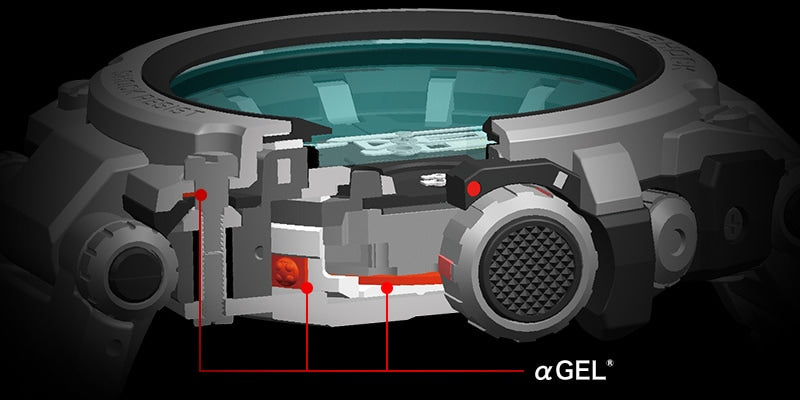

Vibration-resistant structure

αGEL® (Alpha GEL)* is packed around the module as an insulator to absorb vibrations and prevent damage and malfunctions resulting from violent vibrations. Aluminum band washers and O-rings are inserted to prevent the screws that connect the band to the case from loosening due to vibrations.

Vibration resistance testing

Testing is conducted by a testing machine that generates vibrations with various magnitudes and speeds of amplitude. Vibration resistance performance is confirmed by the Vibration Testing Methods for Automobile Parts (JIS D1601 4 type A) with reference to the grade (vibration acceleration up to 20 G) required for in-vehicle devices for two-wheeled vehicles.

Skip to content

Skip to content